Revised Lead and Copper Rule (RLCR) Revisions | Service-Line Inventory Guidance

The KnowYourH2O Team is always looking for solid resources to help educate and inform the licensed professional engineer, water system operator, water company or authority management teams, and other water quality professionals. The topic of this discussion is the “Revised Lead Service Line Rule.” For this topic, there are guidance documents, workshops, training sessions, and webinars, but sometimes it is good to have a one-stop resource to assist with getting to the facts.

On August 4, 2022, the EPA released Guidance for Developing and Maintaining a Service Line Inventory to support water systems with their efforts to develop inventories and to provide states with needed information for oversight and reporting to the EPA. The guidance provides essential information to help water systems comply with the Lead and Copper Rule Revisions requirement to prepare and maintain an inventory of service line materials by October 16, 2024. For that purpose, the following documents or tools were made available (Press Release):

Guidance for Developing and Maintaining a Service Line Inventory (pdf) (6.8 MB, August 4, 2022, 816-B-22-001)

EPA’s new Guidance for Developing and Maintaining a Service Line Inventory:

- Provides best practices for inventory development and risk communications.

- Contains case studies on developing, reviewing, and communicating about inventories.

- Includes a template for water systems, States, and Tribes to use or adapt to create their own inventory.

- Highlights the importance of prioritizing inventory development in disadvantaged communities and where children live and play.

Inventory Template (xlsx) (1.5 MB, August 4, 2022)

October 16, 2024 is fast approaching. In preparing this blog post we partnered with Entech Engineering from Reading, Pennsylvania and we present this information in an interview format. The professional we interviewed was Christina (Tori) Morgan, LO, Compliance Director/Senior Project Manager and Director of Funding, Regulatory Relations, and Compliance at Entech Engineering.

Below are a few of the most pertinent questions:

Question 1: What is a Service Line? And is the service line owned by the Water Company or Authority, the local municipality, the water customer, the building owner, or someone else?

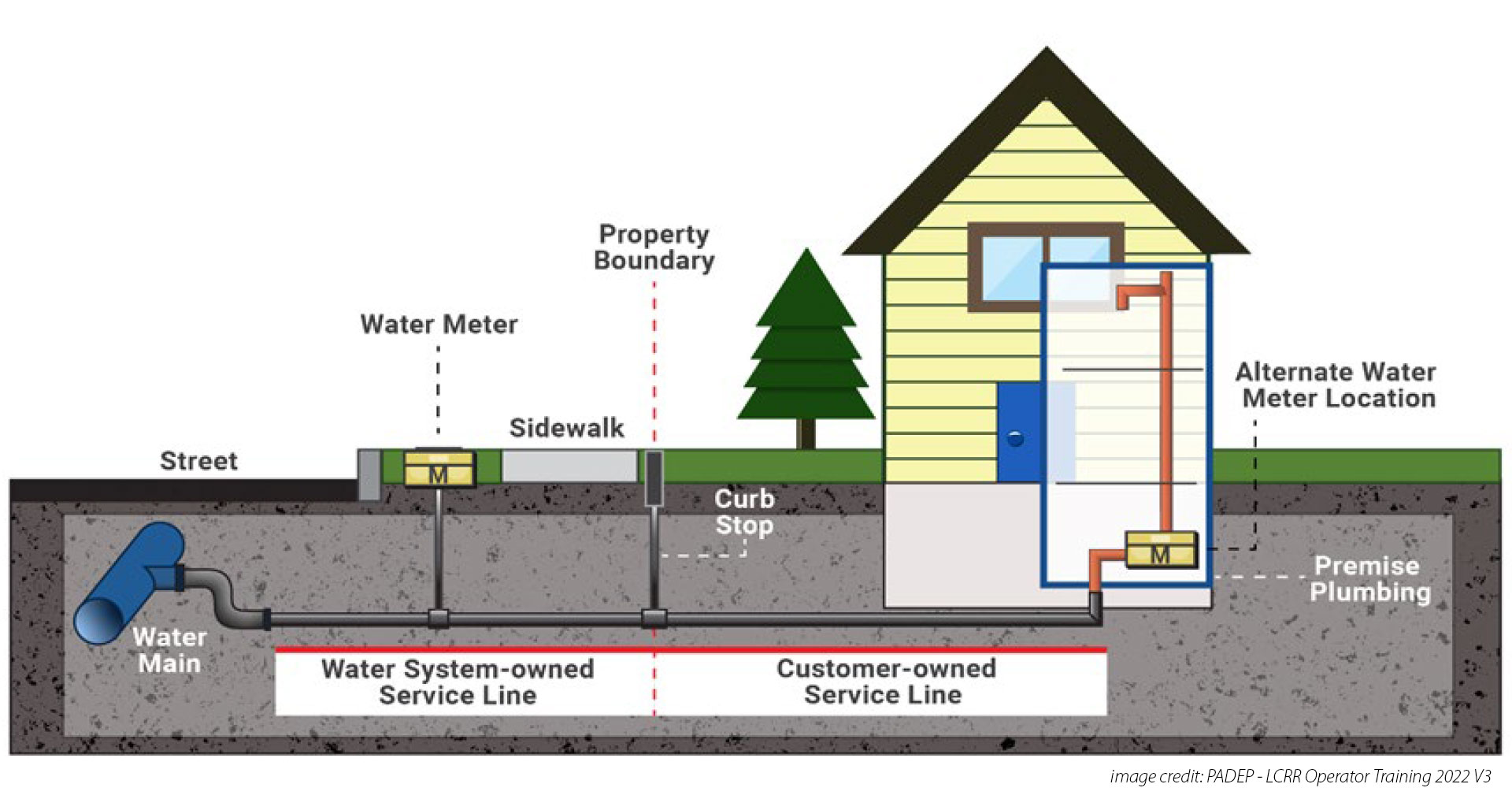

Tori: The easiest way to answer this question is possibly all the above; let’s first start by looking at this image provided by the PADEP (Pennsylvania Department of Environmental Protection). This image is used in the PADEP’s LCRR (Lead & Copper Rules Revision) Service-Line-Inventory Operator-Training-Manual. From this illustration, it is clear that the service line is the “lateral” that is connected to the water main that services a building, home, or other structure and whose ownership is divided into at least two components: “Water System-Owned Service Line” and “Customer-owned Service Line.” When reviewing this graph, the dividing line between these two portions is typically the “Property Boundary” and therefore, the “Customer-owned Service Line” is likely under the control and ownership of the owner of the property in question. Therefore, it is possible that the user in the building may not be the owner of the building; there is a renter.

Question 2: What is the Lead Service Line (LSL) Inventory requirement?

Tori: As per the Revised Lead and Copper Rule | US EPA (RLCR), water systems must submit a service line inventory, identifying service lines as lead, non-lead, galvanized requiring replacement (GRR), or lead status unknown, along with an associated LSL Replacement Plan by October 16, 2024. The primary difficulty with this regulatory mandate is that it is very likely the system or local agency and even the customers may not be sure what material was actually used as part of the service line.

Question 3: What is a lead service line and Is it necessary to change just the lead service lines?

Tori: A service line or lateral is a pipe that connects the water main to a building. If any portion of the service line is lead, the service line is considered to be a lead service line. However, there is an exception for service lines with only a lead gooseneck, pigtail, or connector in which case the service line is not considered to be a lead service line under the RLCR.

A galvanized (zinc-coated steel pipe) service line in which any portion of the pipe was downstream of any portion of a LSL, lead gooseneck, pigtail, or connector, or service line of unknown materials, is considered to be galvanized-requiring-replacement (GRR).

Because there is no safe level of lead, the primary assumption is that all service lines are lead service lines until they are proven not to be lead service lines.

How to Prove Non-Lead Service Lines Flow Chart PDF

Question 4: With the deadline approaching, how much time should we plan or allocate to completing this initial lead service line inventory?

Tori: Since each public water system is different, there is no easy answer to the amount of time that will be required. We strongly recommend that all systems take this very seriously and begin to compile any information about their systems and immediately begin with a professional to help you complete the data gap analysis, compile associated data, begin the investigation, and develop a verification methodology to help identify the lead services lines within your community or target area. The main reason we are encouraging a proactive effort is because the EPA is handling all enforcement related to the RCLR; on a federal level, failure to complete a service line inventory by the compliance date is considered a health-based violation.

There are a lot of other questions on this issue related to the requirements of the inventory, trying to prove that Non-Lead Service Lines are present in your distribution network and Entech Engineering has a great toolkit to help you on your Path To Clean Water and to Getting the Lead Out. Visit their site to Learn More.

Take a look at the photos below. You can tell a lot about your water just by what you see. This is an example of Level 1 Testing.

A service line identification request and accompanying photo.

About Tori Morgan, Entech Engineering

Tori Morgan is the Director of Funding, Regulatory Relations, and Compliance. She is a graduate of Muhlenberg College in Biology and Psychology. Tori brings thirty years of diverse experience in compliance management, industrial pretreatment, and quality control, health & safety fields, and regulatory support. At Entech, Tori takes the lead on centralizing regulatory and compliance work to help ensure clients stay abreast of regulatory changes by developing and maintaining a database for tracking their client’s permitting needs, expanding Entech’s industrial pretreatment portfolio, and mentoring other employees. Tori’s experience includes supervision, compliance management, environmental audits, budget preparation, operations, safety, laboratory, compliance software management, industrial pretreatment, FOG program development, and regulatory support. Recently, she has led Entech’s Funding Team to help clients find the best sources of grants and loans to get municipal projects moving forward. She is also a certified water and wastewater operator in Pennsylvania and New Jersey.

She is also active in PA AWWA, EPWPCOA, and the Lehigh Valley Chamber Energy and Environment Committee. In addition to Tori’s technical achievements, she serves on multiple public and community service boards including LV Pretreatment Information Exchange (PIX), Parkland Cares Food Pantry, Lehigh Valley Planning Commission (current Vice Chair), Parkland School District Education Foundation (current President), Western Lehigh Chamber of Commerce, and has also served as a Commissioner for South Whitehall Township for 14yrs.

Related Educational Courses

Lead Contamination of Public Water Systems

Protecting Water Systems Through Backflow Prevention

Drinking Water Quality - Monitoring & Security

Online PDH Courses and Webinars for Engineers

Suggested Reading

The Poisoned City: Flint's Water and the American Urban Tragedy

Mathematics Manual for Water and Wastewater Treatment Plant Operators

Links to Water Testing Kits and Services

National Testing Labs – Corrosion Check

Tap Score – Mineral Test of Drinking Water